Case Study on GHGs Mitigation by the Renewable Energy Utilization of Organic Wastes at Marikina River Basin (MRB) in the Philippines

Abstract

This case study was worked out as part of the project ʺRestoration of Ecosystem Service and Conservation of Carbon Sink in the Marikina River Basin in the Philippinesʺ. Especially, it focuses on abating GHGs emissions and generating renewable energy through methane waste management in the region. The general information was collected through a literature review and then, the local situation was identified through meetings with local stakeholders. In addition, the field survey was conducted to investigate the operation of renewable energy production facility through biogas from biodegradable organic waste. Based on the site survey results, the most applicable technologies and facility designs was studied. The proposed prototype model can produce 882 Nm3 / day biogas (55% methane) using 15 m3/day swine slurry and 5 m3/day food waste. Biogas are used to generate 1,611 kWh of electricity a day through engine development. Considering that 20 m3/day of swine slurry and food waste can be reliably handled, about 322 households will be able to use their own electric energy. On the other hand, there is a GHGs effect of 3,611 tCO2eq/year. Given the characteristics of MRBʹs household and livestock waste emissions, the proposed prototype model can be spread throughout the Philippines.

Keywords:

Green climate fund, Organic waste, Anaerobic digestion, Renewable energy, Marikina river basin1. Introduction

Marikina River Basin (MRB) region in the Philippines is a huge river basin comprising of 69,826 ha near the Metro Manila (Berkman, 2015). It is currently experiencing urbanization in line with rapid population growth. As a result, inconsistent land use management is destroying ecosystem services in the region. The decline of ecosystem service has made this region very highly vulnerable to climate change. There is rising trend in occurrence of floods and water induced disasters such as landslide within and in the lower catchments of the basin (Berkman, 2015). Recently, the need of ecosystem based adaptation and mitigation to the impacts of climate change is rapidly emerging in MRB. It is critical to reduce the vulnerability of ecosystems and increase the resilience to climate change in order to maintain sustainable management, conservation, and restoration of ecosystems in the region (Cruz, 2018).

Livestock production has rapidly expanded in many Asian countries during the last decades in response to rising demand for animal products due to increasing population and urbanization. This expansion is expected to continue and will increase the demand for land to produce high-quality feeds and forages. Consequently it accelerates the production and accumulation of animal wastes. Livestock waste is very beneficial for plant growth, improving soil structure and increasing soil fertility. If used properly, it can replace a significant amount of chemical fertilizers. However, if animal manure is not carefully managed to minimize emissions, it becomes a source of Greenhouse Gases (GHGs) emissions and furthermore a direct threat to human. In manure, carbon in the form of CH4 and nitrogen in the form of N2O are 21 and 310 times more harmful than CO2, respectively, in causing the Global Warming Potential (GWP).

In the MRB, waste is the largest source of GHGs emission (6,521 Gg CO2eq, 81.6%). This figure is very high compared to 56% share of the GHGs in waste of national GHGs inventory (Buendia and Lasco, 2019). The amount of emission in rest of the sector is very small. The emissions of the Land-Use and Land-Use Change and Forestry (LULUCF) sector is approximately 73 Gg CO2eq (Buendia and Lasco, 2019). The national LULUCF sector is a carbon sink, while the deforestation and land use changes in the region over the last decades have made LULUCF as source of emissions. Most of the waste from MRB comes from household waste and agricultural waste (livestock and crops/plants) at residential/settlement areas (ADB (c), 2013). Most of these are biodegradable waste, which accounts for an average of 50% of waste. Of the total GHG emitted from livestock, CH4 produced from enteric fermentation had the highest percentage (60%) which largely came from ruminant animals like swine, carabazo, cattle, and goats. The remaining 40% came from emissions of CH4 and N2O from the management of the animal manure (Buendia and Lasco, 2019).

The problem of waste disposal in MRB has been rising as an urgent problem for mitigation of climate change. This case study focuses on reducing the increase of GHGs from livestock and household biodegradable waste accumulation in residential areas of the MRB and furthermore on establishing ways for sustainable development through generating renewable energy by organic waste management in the MRB region. The objective of this case study is to develop the prototype model for biodegradable waste management from both household and livestock (especially swine manure) in Municipalities (Antipolo City, Baras, Tanay, Rodrigues, San Mateo) at MRB.

2. Status of survey area

2.1 Biodegradable organic waste from livestock

The Philippines’ agriculture, hunting, forestry and fishing (AHFF) sector accounted for 7.1% of the total GDP (PAS (a), 2019). Livestock production reached 17.75% in total agricultural output and increased by 3.22% in the second quarter of 2019 (PAS (b), 2019). As meat and milk consumption increase, programs that promote livestock productivity are a key part of the government's mid-term plan. Livestock industry in the Philippines is showing positive growth due to the increase in meat demand resulting from improvement in the national economy (PSA (b), 2019). Meat consumptions are expected to increase as a result of the rapidly increasing Philippine population. As a consequence, CH4 and N2O emissions from enteric fermentation and manure management are expected to increase with the increasing demand for livestock products (Buendia and Lasco, 2019).

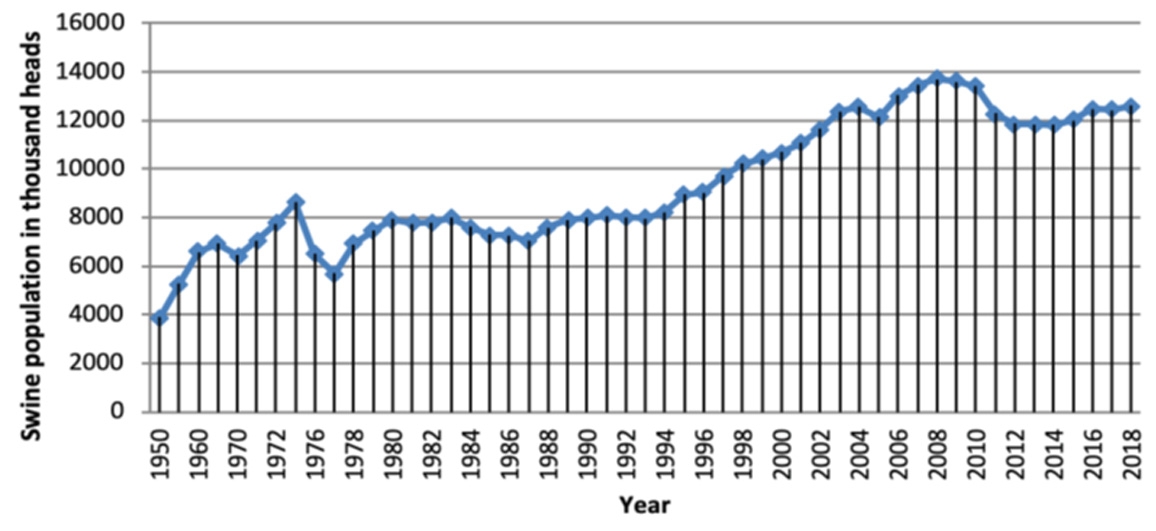

As fig. 1 shows, swine population continues to grow considerably from 3.8 million heads in 1950 to as high as 13.7 million heads in 2008 (PSA (c), 2019).

As of July 2019 (PAS (c), 2019), the total inventory of swine was estimated at 12.53 million heads, representing a decrease of around 9% compared with its previous year’s stocks heads. Population of swine in backyard farms of 8.06 million heads contracted by 1.2% from the previous year’s count heads. On the other hand, stocks in commercial farms at 4.68 million heads expanded by 0.4% from the previous year’s heads (PAS (c), 2019). Among the regions, Central Luzon recorded the highest swine inventory of 2.14 million heads. This was followed by Calabazon (5 Municipalities: Antipolo City, Baras, Tanay, Rodrigues, San. Mateo belongs to Calabazon) with stocks of 1.55 million heads. The combined stocks of these 2 regions accounted for 29.5% of the country’s total swine inventory (table 1).

As the production systems that concentrate livestock animals in confinement are becoming popular, the swine and poultry farms have produced significant amounts of animal waste. The key issues and features of each Local Government Unit (LGU) were identified at stakeholder meetings as follows. LGU Antipolo City will provide incentives to farmers that plan to relocate to the designated agro-industrial area in Pinugay. Centralizing infrastructure support facilities makes it easier for LGU to monitor small-scale farmer and supply them with incentives and other support packages for their expansion. At LGU Tanay, septic tanks must be installed for raising pigs in the watershed (more than 100 ha). They would also need to have a Pollution Control Officer (PCO) assess their discharge. Otherwise, for every 2 units of pigs, they would be required to secure a discharge permit worth PhP 3,000 (55 US$). In LGU Baras, because toxic human waste coming from the watershed reaches Laguna de Bay and eventually Manila Bay, it is critical issue to protect Manila Bay. Table 2 is the current status of piggery (hog/swine) farms of each municipalities discussed at the stakeholder meeting in Manila, on Sept. 20183.

2.2 Amount of biodegradable organic waste in study area

“Owned manually flushed” is the most popular type of toilet used by the respondents4 in five municipalities covered by MRB (ADB (b), 2013). In Antipolo City, 86% of the respondents claimed to have this type of toilet. In Rodriguez, it was mentioned by 81% of the total respondents. In the remaining 3 municipalities: Tanay, Baras and San Mateo, this type of toilet comprised 80% of the total responses received. The remaining 14-20% of the total responses is shared by the other types of toilet present in the municipalities such as the flush system, communal manually flushed, buried, open pit and open defecation (ADB (b), 2013). There are more respondents who said that their wastes are biodegradable as compared to those who indicated that their refuse are non-biodegradable although their ratio varies with municipality (ADB (b), 2013). Broken down as: Antipolo City-55% (biodegradable) / 31% (non-biodegradable); Baras-55% (biodegradable) / 30% (non-biodegradable); Tanay-67% (biodegradable) / 33% (non-biodegradable); San Mateo-55% (biodegradable) / 45% (non-biodegradable) and Rodriguez-43% (biodegradable) / 50% (non-biodegradable); Average waste generation per household per week was Tanay (2.99 kg), Antipolo (2.69 kg), San Mateo (2.19 kg), Baras (2.03 kg), Rodriguez (1.94 kg). Over-all MRB was 2.18 kg per household/week (table 3).

3. Applicable Biogas Technologies Study

3.1 Biogas Technologies

The purpose of this study is to establish a system to mitigate GHG effects through recycling of energy and nutrients from swine wastes and household biodegradable waste as an important component of the national efforts on minimization of GHGs in the Philippines. The anaerobic digestion technique producing methane gas from strong organic wastes is the production method of alternative energy substituting fossil oil and the very effective disposal method of organic wastes reducing GHG.

Anaerobic digestion (AD) is a naturally occurring biological process that uses microbes to break down organic material in the absence of oxygen. In engineered anaerobic digesters, the digestion of organic waste takes place in a special reactor, or enclosed chamber, where critical environmental conditions such as moisture content, temperature and pH levels can be controlled to maximize gas generation and waste decomposition rates. One of the by-products generated during the digestion process is biogas, which consists of mostly methane (ranging from 55% to 70%) and CO2. The benefit of an AD process is that it is a net generator of energy. From the energy produced by the AD facility, depending on the technologies, only maximum of 15% is required for the AD facility itself. The level of biogas produced depends on several key factors including the process design, the volatile solids in the feedstock (composition of the feedstock) and the Carbon/Nitrogen (C: N) ratio. The mostly used AD technologies which fit for several biomass production are broadly defined as bellows (table 4).

3.2 Technology proposal: Semi dry anaerobic digestion (Plug & flow reactor)

This process has been studied to treat a biomass with a content in solid waste of 15-20%. The plug & flow reactor (PFR) gives the advantage to have a smaller reactor with a reduction in the investment costs because solid waste is directly utilized as the process input materials without water dilution (table 5). The system need to work with very viscous material. The equipment is more expensive than the wet AD.

On the other hand, the dry AD does not need many pre-treatments. The waste are not diluted. The only pretreatment is a screening to take out the junk materials over 40 mm. Because the loss of material is very low, the system works better with biomass coming from source sorting collection. Due to the viscosity of the material the reactor does not use CSTR but pistons plug-flow which have a simplified but stronger mechanic.

4. Feasibility results

4.1 Basic design of biogas production plant

- 1) Input capacity: 20 m3/day

- 2) Digester capacity: 600 m3 (HRT 30 days)

- 3) Process temperature: 38°C

- 4) Input design: 20 m3/day (swine waste 15 m3/day, household biodegradable waste 5 m3/day)

4.2 Pilot project plan as feasibility test

Commercial swine farm will install an anaerobic digester of 20 m3/day input scale and a co-generating system of 80kW for commercializing use. The anaerobic digester is capable of producing biogas about 882 Nm3/day, and the co-generating system can convert the produced biogas to the electrical power of 1,611 kWh/day. Also the estimated amount of produced energy and mitigated CO2 were 4,197 Mcal /day and 2,034 ton tCO2eq /year respectively (Table 6).

In addition to the GHG mitigation effects through bio-gas power plants, the calculation of the reduction amount of GHG is taken the effect of efficient management of livestock manure into account. This supplementary opinion will be based on the LCA methodology after surveying the status of the disposal of existing organic wastes in the actual project area. A procedure is required to assess GHG emissions. In our case of the assessment, baseline was placed in composting to yield additional GHG emissions (table 7).

Regarding bio-gas development using household waste, the validity result was supplemented by reviewing the applicability of the household waste level. This issue seems to have been caused by the fact that household waste has occurred in a distributed manner, which makes it difficult to collect it. In case that it is difficult to collect household waste, food waste, etc., it is possible to consider the introduction of the by-products (e.g., slaughtering residues, etc.) from food processing plants.

5. Conclusions

This case study focused on generating renewable energy and abating GHGs emission through organic waste management at MRB region in the Philippines. The proposed prototype model can produce 882 Nm3 / day biogas (55% methane) using 15m3/day swine slurry and 5m3/day food waste. Biogas are used to generate 1,611 kWh of electricity a day through engine development. Considering that 20 m3/day of swine slurry and food waste can be reliably handled, about 322 households will be able to use their own electric energy. On the other hand, there is a GHGs effect of 3,611 tCO2eq/year.

In addition to greenhouse gas reductions, this case study of producing renewable energy from biogas from wastes suggests effective mitigation measures to cope with climate change with sustainable development. Given the characteristics of MRB's household and livestock waste emissions, the proposed prototype model is likely to spread throughout the Philippines.

As mentioned, concept note on “Restoration of Ecosystem Service and Conservation of Carbon Sink in the Marikina River Basin in the Philippines” was submitted to the GCF by KEITI. Regarding GHGs Reduction and Renewable Energy Generation through Methane Waste Management, the summary of its technical and financial feasibility was attached for review. Once the concept note has been approved in accordance with GCF's procedures, a formal business plan should be developed. The consultations with the LGU will be made to determine the site where the pilot project will be implemented. A negotiation with the LBP is going to be planned for financial framework. For the biogas production plant, the design and construction possibility of Korean domestic companies will be reviewed.

Acknowledgments

The project “Restoration of Ecosystem Service and Conservation of Carbon Sink in the Marikina River Basin in the Philippines” was funded by the Green Climate Fund (GCF) Business Development Support Program of the Korea Institute of Environmental Industry and Technology (KEITI) in 2018. And the research and stakeholder meetings of the project took place in cooperation with the Philippine World Agriculture and Forestry Center (Dr. Lasco, Rodel D., the 2007 co-winner of the Nobel Peace Prize) and Land Bank of the Philippines (V.P. Calado, Prudy).

Notes

References

- Asian Development Bank (ADB (a)), 2013, FINAL REPORT, TA-8111 PHI: Climate Resilience and Green Growth in the Upper Marikina River Basin Protected Landscape: Demonstrating the Eco-town Framework (46225-001)

- Asian Development Bank (ADB (b)), 2013, BASELINE INFORMATION AND VULNERABILITY ASSESSMENT REPORT, TA-8111 PHI: Climate Resilience and Green Growth in the Upper Marikina River Basin Protected Landscape: Demonstrating the Eco-town Framework (46225-001),

- Asian Development Bank (ADB (c)), 2013, VULNERABILITY ASSESSMENT OF UMRBPL’S AGRICULTURAL SECTOR, TA-8111 PHI: Climate Resilience and Green Growth in the Upper Marikina River Basin Protected Landscape: Demonstrating the Eco-town Framework (46225-001)

- Asian Development Bank (ADB (d)), 2013, GHG INVENTORY REPORT, TA-8111 PHI: Climate Resilience and Green Growth in the Upper Marikina River Basin Protected Landscape: Demonstrating the Eco-town Framework (46225-001)

- Asian Development Bank (ADB), 2015, TA 8493 PHI: Climate Resilience and Green Growth in Critical Watersheds (46441-001)

- Berkman International Inc. 2015, Formulation of an Integrated River Basin Management and Development Master Plan for Marikina River Basin (Vols. 1-7) for the River Basin Control Office Department of Environment and Natural Resources.

- Buendia, Leandro V. and Lasco, Rodel D., 2019, 2018 Philippine Climate Change Assessment: Working Group 2 Mitigation of Climate Change, Oscar M. Lopez Center

- Cruz, Rex Victor O., 2018, 2017 Philippine Climate Change Assessment, Working Group 2 Impacts, Vulnerabilities and Adaptation, Oscar M. Lopez Center

- ENVIRONMENTAL AND SOCIAL MANAGEMENT PLAN (ESMP), 2019, Bontoc Multi-Purpose Cooperative (BCCI Piggery), Methane Recovery and Power Generation Project, Ref. No. 5979-0008 CPA-22 Methane Recovery and Combustion with Renewable Energy Generation from Anaerobic Animal Manure Management Systems under the Land Bank of the Philippines' Carbon Finance Support Facility

- ETS Insight, 2019, CLIMATE CHANGE RESEARCH INSTITUTE OF KOREA

- Land Bank of the Philippines (LBP), 2015, BCCI PIGGERY FARM STAKEHOLDERS’ CONSULTATION

- Philippine Statistics Authority (PAS (a)), 2019, Performance of Philippine Agriculture; [accessed 2019 Oct 20]. https://psa.gov.ph/nap-press-release/sector/Agriculture,%20Hunting,%20Forestry%20and%20Fishing, .

- Philippine Statistics Authority (PAS (b)), 2019, Performance of Philippine Agriculture; [accessed 2019 Oct 20]. https://psa.gov.ph/ppa-main/livestock-poultry, .

- Philippine Statistics Authority (PAS (c)), 2019, Swine Situation Report; [accessed 2019 Oct 20]. https://psa.gov.ph/gsearch?%2F=Swine+Situation+Report, .

- Forest Management Bureau, 2017, THE ROLE OF FORESTS IN SUPPORTING LIVELIHOODS AND CLIMATE RESILIENCE, Case Studies in the Philippines (UMRBPL)